SKYLINE CORPORATION

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SKYLINE CORPORATION

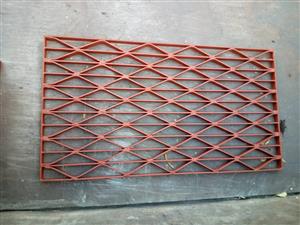

F. R. P. Pultruded Products

We offer a wide range of pultrusion products for the Pultrusion process. Pultrusion is a continuous, automated closed-moulding process that is cost effective for high volume production of constant cross section parts. The basic process usually involves pulling of continuous fibers through a bath of resin, blended with a catalyst and then into pre-forming fixtures where the section is partially pre-shaped & excess resin is removed. It is then passed through a heated die, which determines the sectional geometry and finish of the final product.

Advantages of FRP Pultruded Products

- Corrosion Resistant.

- Weather Resistant.

- Lightweight.

- High Strength.

- Electromagnetic Transparency.

- Non-Conductive.

- Electrically Insulating.

- Easy to Fabricate & Install.

- High Dimensional Stability.

- Flame Retardant.

Products

Round rods, rectangles, squares, ‘I’ sections, ‘T’ sections, angles, channels, dog

bone profiles, dove tail sticks and spacers, corner profiles, hallow sections, etc.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.